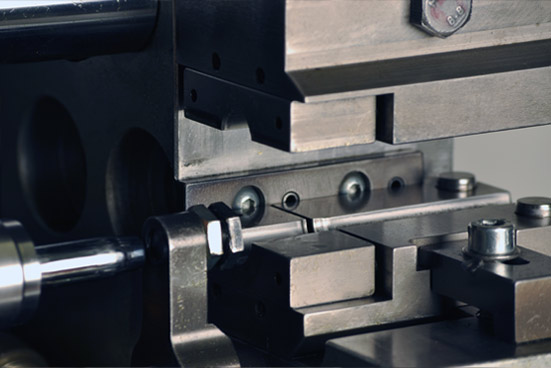

Acme offers single or multiple-stroke end forms up to 1/2″ in diameter. Our highly qualified team works with deliberate and painstaking attention to detail, quality, and precision.Tube ending for single or multiple-stroke end forms up to 1/2″ in diameter requires exceptional precision, as small tubes demand tighter tolerances and meticulous control compared to their larger counterparts. Accuracy is critical for small tube end forming due to its applications.

End Forming Accuracy and Applications

Due to the importance of small tubes in different industries, end forming is critical for making these tubes effective in their application. Acme Tube Bending can do the following types of end forming:

- Flaring: Creates a widened, conical end on a tube to allow for secure connections, often for gas or fluid lines. Widely used in Automotive (e.g., brake and fuel lines) and HVAC (refrigeration lines). Small-diameter flares ensure leak-proof connections with fittings for fluid or gas systems

- Beading: Forms a raised, rounded ridge or bead around the tube’s end, enhancing structural strength or enabling connections like hose attachments. Frequently applied in Automotive Exhaust Systems (e.g. for hose or muffler attachments) and HVAC (refrigerant or air lines). Beading strengthens tube ends for secure house clamping in low- to medium-pressure systems

- Swaging: Reduces or reshapes the tube’s end into a different diameter or shape (e.g., tapered or profiled) to fit into another component or create a specific flow path. Common in Medical (e.g., catheter or surgical instrument tubing) and Aerospace (lightweight fuel or hydraulic lines). Swaging creates precise, tapered ends for fittings or flow control in small, high-precision components.

- Reduction: Decreases the tube’s end diameter to fit inside another tube or fitting, ensuring a tight connection. Used in Automotive (fuel lines, brake systems) and Industrial Machinery (hydraulic or pneumatic systems). Reducing tube ends ensures tight fits into connectors or manifolds, critical for high-pressure applications

- Expansion: Increases the tube’s end diameter to fit over another tube or component, often for telescoping or joining purposes. Applied in HVAC (heat exchanger tubing) and Automotive (cooling or intake systems). Expanded ends allow small tubes to fit over larger components.

- Double Flaring: A two-step flaring process creating a stronger, more durable flared end. Critical in Automotive Brake Systems, where 3/16″ to 1/4″ tubes are standard. Double flaring provides a robust seal for high-pressure fluid lines, meeting strict safety standards (e.g., SAE J533 for brake lines).

- Chamfering: Bevels or angles the tube’s end to remove sharp edges, ease insertion into fittings, or prepare for welding. Common in Aerospace and Medical for preparing tube ends for welding or insertion into fittings. Chamfered edges on small tubes reduce wear on seals and ease assembly in precision applications.

- Flattening: Compresses the tube’s end into a flat shape, often for mounting, securing, or creating a specific contact surface. Used in Furniture Manufacturing (e.g., chair or table frames) and Small Machinery (mounting brackets). Flattening creates mounting points or structural supports for lightweight, small-diameter tubes.

Each of these options has pros and cons. We are happy to help you evaluate the right decision for your particular application.

Request a Quote

Request a quote for additional information regarding the price and feasibility of your custom project. We make every effort to reply to inquiries within one business day.